جهت استعلام قیمت و مشاوره رایگان، تماس بگیرید

(09176050698 و 37742637-071)

Food can be frozen slowly or quickly. In the slow freezing method, the desired materials are placed in a low temperature space to be slowly frozen. There are several ways to freeze quickly, including direct contact of the product with the freezer, indirect contact of the product with the freezer, and the passage of intense cold air. Cold and intense air flow usually takes place inside a special tunnel.

Products that are frozen must be of high quality. In the case of vegetables and fruits, choosing the right type of product for freezing is very important because some of them are not suitable for freezing and after freezing, they become low quality products.

Frozen vegetables and fruits should be picked when fully ripe and frozen immediately to prevent adverse chemical changes by enzymatic and microbial reactions. Before freezing vegetables and fruits, operations are performed on them in such a way that after cleaning and washing these products, to remove foreign substances such as leaves, dirt, insects and sap from their surface and eliminate natural enzymes in vegetables Wash them in hot water or steam at 100 degrees Celsius.

It should be noted that enzymes are not destroyed at low temperatures and even at low temperatures of -18 and below, they continue to function lightly. Therefore, the above method, which destroys the enzyme, increases the life of vegetables. The time required for washing depends on the type of vegetable and varies from one to one and a half minutes for green beans to eleven minutes for large clusters of cereals. Although most microbial contaminants are eliminated during the steam washing process with enzymes, most bacteria survive and to prevent vegetables from spoiling by these bacteria, they must be cooled to 10 ° C after washing and before packaging. .

Fruits should be cleaned and washed like vegetables to remove foreign matter and reduce microbial contamination. Although fruits are more susceptible to enzymatic spoilage than vegetables, they are never steam-washed to kill natural enzymes, as doing so will destroy the fresh quality of the fruit.

The enzymes involved in fruit freezing are those that accelerate oxidation and cause rapid breakdown of the fruit kernel. To control the oxidation intensity of frozen fruit, it is covered with diluted sugar syrup. In some cases, ascorbic acid, citric acid or sulfur dioxide are also used for this purpose.

In general, meat products do not require any operation before freezing, but according to consumer demand, large quantities of meat and meat products are prepared and frozen in special ways. This also applies to chicken and seafood.

Due to the relative instability of their adipose tissue, fish are usually frozen immediately after cooling, but beef is placed in the freezer for several days before freezing, during which time it is somewhat crushed by enzymatic activity. This will reduce the life of the meat, especially if it exceeds six or seven days. Experiments show that if the chicken is frozen 12 to 24 hours after slaughter, it will be crispier than chicken that was frozen immediately after slaughter, but a delay of more than 24 hours in freezing, without a significant increase in the crispness of chicken meat, will preserve its shelf life. decreases.

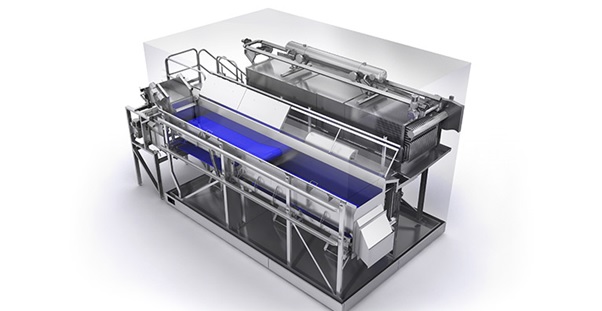

Freezing tunnel is a hall with a cooling power of about -30 to -60 degrees Celsius, which can completely freeze the desired product by reducing the temperature of the desired food product such as meat, fish and… and passing them through the crystallization stage. .

One of the advantages of using freezing tunnels to freeze food is the short time required. Rapid freezing prevents the formation of large ice crystals in the products. These large crystals reduce the quality of the desired food. Therefore, rapid freezing largely preserves the shape, color, odor and taste of the product. Another advantage of using freezing tunnels is the possibility of separating the products one by one during freezing, which results in a higher quality product than in the case of mass freezing. This issue is as important as the customer needs in terms of food shelf life and use.

The frozen food market is growing rapidly. Companies want to freeze their food products and sell them differently. A freezing tunnel is a system that uses a conveyor belt to continuously freeze foods such as berries, small fish, meat, and so on. Most freezing tunnels are currently focused on freezing speeds.

The Quick Freezer Tunnel, or Individual Quick Freezer, is used to freeze products such as vegetables, fruits, poultry, shrimp, fish, ice cream, meat, and instant prepared foods. It fully preserves the properties and quality of the products and will prevent the food tissues from sticking together during the freezing process.

Rapid freezing tunnels, or IQFs, are designed and offered for use in both spiral and linear models. These tunnels are designed in accordance with international standards of FDA, USDA, CFIA, UL, CSA, OSHA and are one of the best tunnels offered for fast food freezing.

Vote that products such as vegetables, fruits, juices, beer, meat, poultry, seafood and eggs (without box) be stored for a longer period of time at -18 degrees and maintain their quality and freshness as well as the first day.Freezing tunnel is used. Not only can these foods be frozen in the freezing tunnel, but certain foods such as breads, ice cream, cooked and canned foods can also be frozen well in the freezing tunnel for long-term storage.

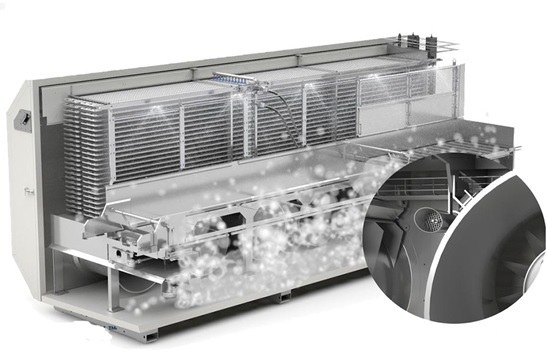

There are generally two methods for rapid freezing. A mechanical method based on the passage of cold air flow. A stream of cold air passes around the products with the help of a fan and freezes them. Another method is to immerse the products in liquid nitrogen at a very low temperature, which causes immediate freezing.

Freezing tunnel is one of the mechanical methods of rapid freezing. Freezing tunnels used in the rapid freezing process can be divided into linear and spiral freezing tunnels. Also, the freezing tunnel can be equipped with a conveyor belt depending on the intended application. This option is mostly used in production lines. Linear freezing tunnels can have a capacity of up to 12 tons per hour and spiral freezing tunnels up to 3 tons per hour.

This tunnel uses the ability to immerse food in cold weather to freeze food. The capacity of these tunnels is between 200 and 12,000 kg per hour and is used for fast freezing of food.

These tunnels are used to freeze a variety of vegetables such as peas, green beans, beans, sweet corn, mushrooms, french fries, carrots, cauliflower, onions, tomatoes and broccoli.

These tunnels are used for fast freezing of food in production lines and have a freezing capacity of about 100 to 3000 kg. Spiral freezing tunnels can be used to freeze products such as chicken and chicken pieces, chicken fillets and pies, fried chicken, red meat such as meat patties, pieces of meat, raw hamburgers and similar products.

The equipment used in the freezing tunnel is the same as the cold store and includes compressors, evaporators and condensers, expansion valves and electrical panels. There are differences in the control equipment used in freezing tunnels and conventional refrigeration.

What is the difference between a freezer tunnel and a cold store?

The most important difference between freezing tunnels and cold storages is the evaporator type, which is generally standing in freezing tunnels. Also in the freezing tunnel, the freezing speed of the product is very high and the product is placed in the freezing tunnel for a short time (about eight hours).

The opening of the freezing tunnel door is very special, so it has a special design. The material of these doors is generally PVC or polyester inside, and it is an alloy of aluminum and can also have control glass.

The most important parameter involved in the design and construction of the freezing tunnel is the desired freezing capacity, which means that the freezing tunnel can freeze several tons of food per hour. Another important point is the volume of the freezing tunnel, which should be used more evaporators if it is large. The freezing tunnel is designed for temperatures of -40 degrees Celsius and cools food to -18 degrees.

In the slow freezing method, the desired products are placed in a room with a temperature of -18 to -40 and frozen in still and calm air. Because the freezing process is slow, the process of freezing the product may take three hours to three days.

A variety of foods such as beef, canned chicken, fish, canned fruit and eggs (white, yolk or true) in 5 to 15 kg packages are examples of frozen frozen products.

Another method of freezing, called rapid freezing, can be done in one of three ways:

Using cold air

Freezing by indirect contact

Immerse frozen products

Indirect freezing is done by placing food on a cooling plate. As the food is placed on the cooling plate, the temperature of the products decreases depending on the level of contact with the plate. Of course, this method will be justified for products that need to be frozen in small volumes.

There is a type of plate designed for plate freezers that has a set of horizontal and vertical plates for product placement. Then, after placing the food between these plates, cold air is passed around the food for rapid freezing of the products with high intensity, until the food is completely frozen.

In this method, sodium chloride solution or sugar is used to cool the desired products; Because this liquid, despite being conductive, reduces the temperature of food very quickly. The advantage of this method is that the food can be frozen easily without being piled on top of each other, or losing their texture and composition.

One of the main disadvantages of this method is the possibility of penetration of the prepared solution into food packages. Therefore, sugar is used instead of salt to freeze fruits such as oranges, so that the absorption of the solution in the fruits does not cause any problems in their taste and quality.

The method of using salt solution is also used to freeze seafood such as shrimp and fish that will be well preserved in the presence of salt.

دیدگاهها

هیچ دیدگاهی برای این محصول نوشته نشده است.