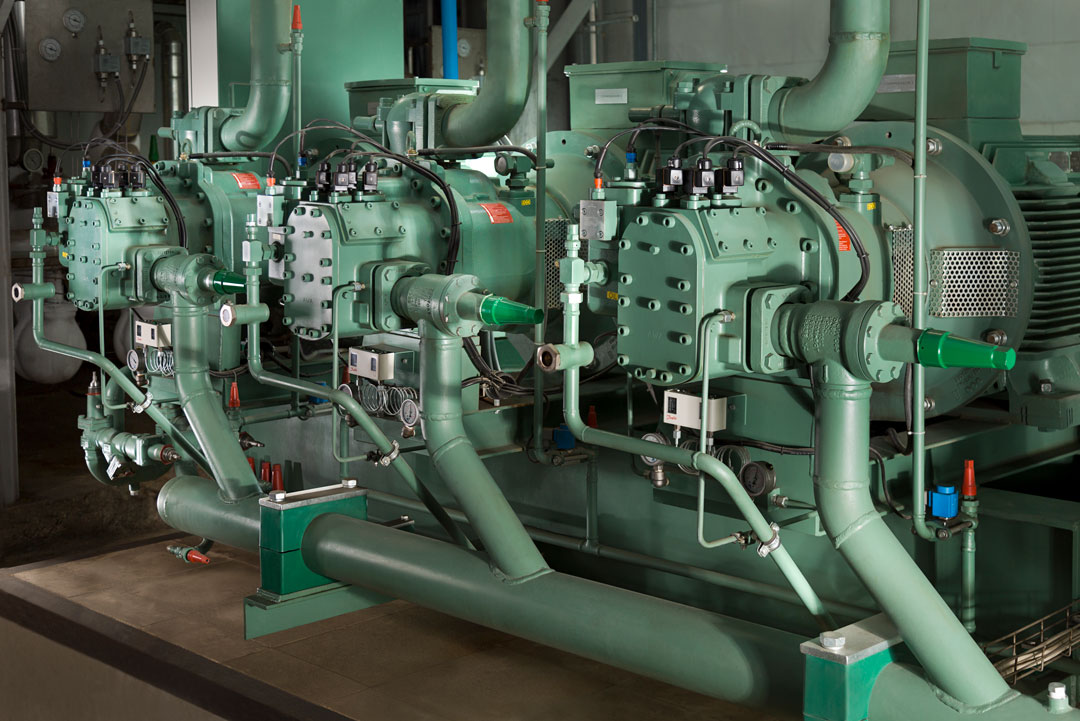

Pioneer and innovator in the industry

Advanced services of refrigeration and heating systems in industrial projects

Kowsar Technical and Engineering Group with more than 30 years of experience in the field of design, consulting, monitoring and implementation of industrial systems in the fields of electricity, mechanics and construction, has a brilliant record.

Activities of the technical and engineering company:

1. Daiti Ice Cream Factory (first and second phase) – Shiraz

2. Tak Afrid Sample Company – Shiraz

3. Mahan Bashir Company – Kerman

4. Bist Ice Cream Company – Kerman

5. Ramak Bita Ice Cream Company – Shiraz

6. Samiran Salamat Cold Storage – Shiraz

7. 7000 ton juicy cold storage of Amiri brothers – Jiroft

8. 7000 ton cold storage of Adel Agro-industry Company – Shiraz

9. Golden Fruit Company cold storage – Tehran

10. Sarma Afarin J – Isfahan cold storage

11. Mahan Bashir Food Industries – Kerman

12. Organ Transplant Hospital – Shiraz

13. Pak Ice Cream Company – Tehran

14. Ishaqi cold storage – Qeshm

15. Sepahan Cold morgue – Isfahan

16. Iran Zam Cold Storage – Lahijan

17. Valiasr Ice Cream – Khormoj

18. Fayouz Freezing – Bushehr

19. Delicious ice cream – Shiraz

20. Weiss Cold Storage – Bandar Abbas

21. Pegah Company – Isfahan

22. Mehr Ice Cream Factory – Isfahan

23. Padam Cold Storage – Tehran

Activities of Poultry Company:

1. 6000-piece clean slaughterhouse in Mashhad – Khorasan Razavi – under the management of Mr. Yousefi

2. Sepid Goosht slaughterhouse in Khorasan – Khorasan Razavi – under the management of Mr. Irannejad

3. Individual industrial slaughterhouse – Khorasan Razavi – under the management of Mr. Anfaradi

4. Gonabad White Meat Industrial Slaughterhouse – Khorasan Razavi – under the management of Mr. Sharafi

5. Jian Morgh Industrial Slaughterhouse – Bushehr – under the management of Mr. Haqqani

6. Shiraz Chicken Industrial Slaughterhouse – Shiraz – under the management of Mr. Shojaei

7. Chakotah Industrial Slaughterhouse – Bushehr

Activities of Hozeh Dam Company:

1. Refrigeration system of Eghlid slaughterhouse

2. Bushehr slaughterhouse refrigeration system

Activities of Aquatic Basin Company:

1. Fish, Shrimp and Seafood Packaging Unit of Mahan Bandar Lengeh Company – Hormozgan Province

Company activities in the electrical sector of the facility:

Design, consulting, installation, maintenance and maintenance of industrial facilities

Circuits related to all the following industrial equipments including:

1. Remote control of industrial systems with the latest technology in the world

2. PLC control systems and industrial electrical panels along with monitoring equipment

3. Instrumentation equipment and its adaptation with PLC units and mechanical control systems

4. Types of generators and diesel generators

5. Refrigeration systems such as ammonia, freon and absorption, etc.

6. Steam systems and heat exchanger switches

7. Types of low, medium and strong pressure switchboards

8. Types of medium pressure posts

9. Types of capacitive banks

10. All electrical circuits of pressure test tanks (receivers, condensers, etc.)

11. Electric circuits of various pumps and industrial pumping systems

Company activities in the construction sector:

Design, monitoring, calculation and implementation:

1. Phase 1, 2 and 3 architectural plans (facilities) and executive plans

2. Executive plans and details of green space and landscaping according to the existing regulations

3. Preparing the terms and conditions and maps required by the departments related to the projects

4. Industrial installation structures using modern world standards with the lowest cost

Company activities in the mechanics department:

Design, consulting, installation, maintenance types:

1. Ammonia, Freon or a combination of the two refrigeration systems as well as absorption refrigeration systems in a variety of industrial, semi-industrial, portal, heavy vehicles and ships

2. Refrigeration and heating tunnels in linear, circular, rapid freezing, cold room and refrigeration systems for long-term maintenance with closed and open cycles in various food, pharmaceutical and other industries.

3. Steam systems in industrial plants

4. Motor house projects, industrial power generators, Diesel House installation

5. Hank air heat exchangers, shell, tube, plate and cooling towers

6. Heavy duty pressure vessels including various types of heat exchangers, receivers, condensers, distributors, suction drums, separators, etc.

7. Refrigeration molds in various industries such as ice cream, ice cream, dairy and other industries.

8. Industrial ice and cold water systems with the least energy losses and the least need for maintenance

9. Microbial contamination reduction lines

10. Transmission lines and stainless equipment in food, pharmaceutical, packaging, refrigeration, etc. industries

11. Upgrading and updating old systems in order to reduce energy consumption and increase safety at the lowest possible cost

12. Fixing defects in refrigeration and steam systems

13. Upgrade most industrial facility systems without Shut Down the entire production line

14. Calculation and installation of various pumps, compressors and industrial pumping systems and related structures